April 2021

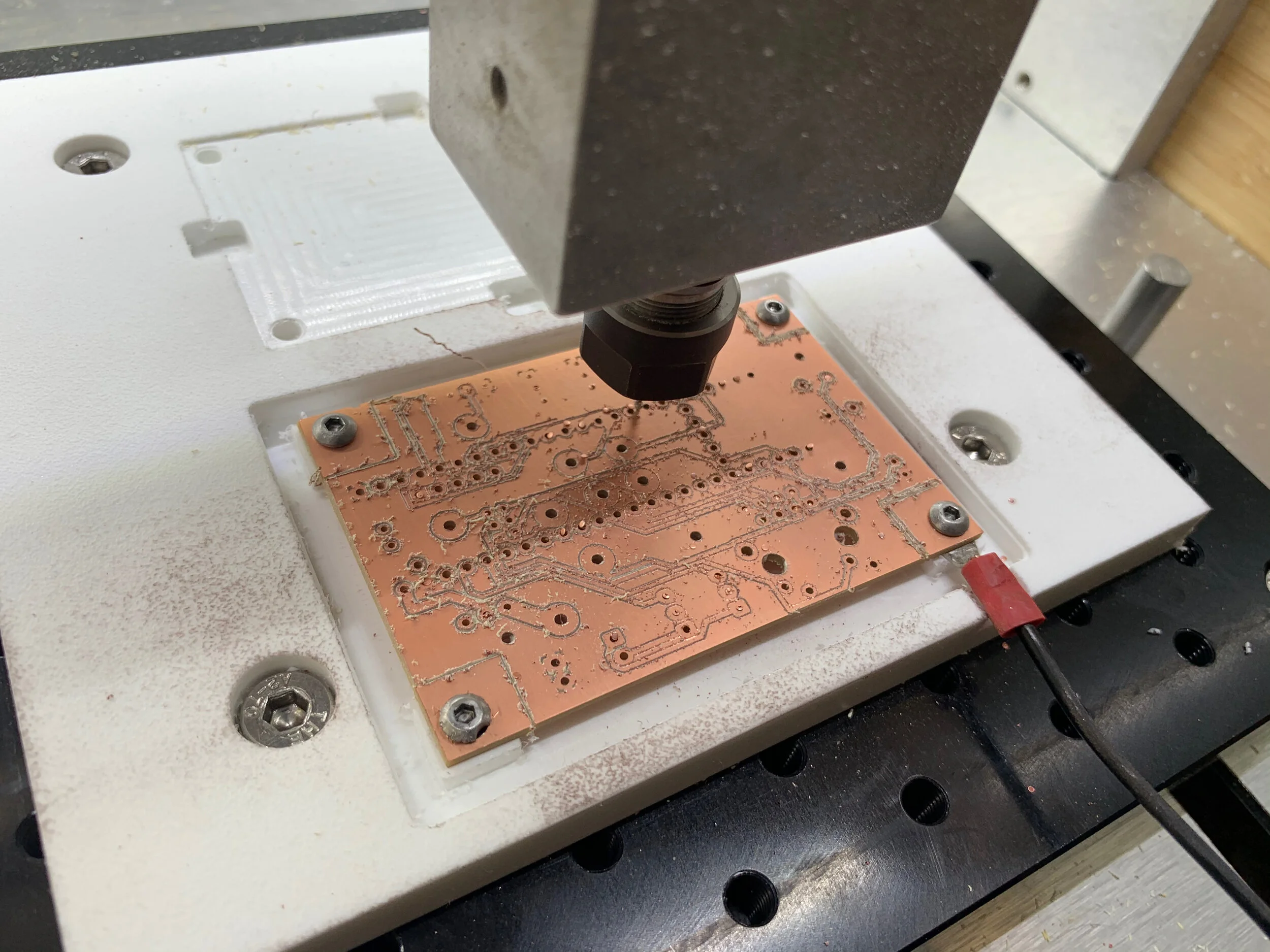

This project details the process of creating prototype PCBs using a home CNC machine. Mastering this skill requires significant time investment—approximately 3-4 weeks of focused effort—though subsequent projects become faster once proficiency is achieved.

The Workflow

The process consists of these main steps:

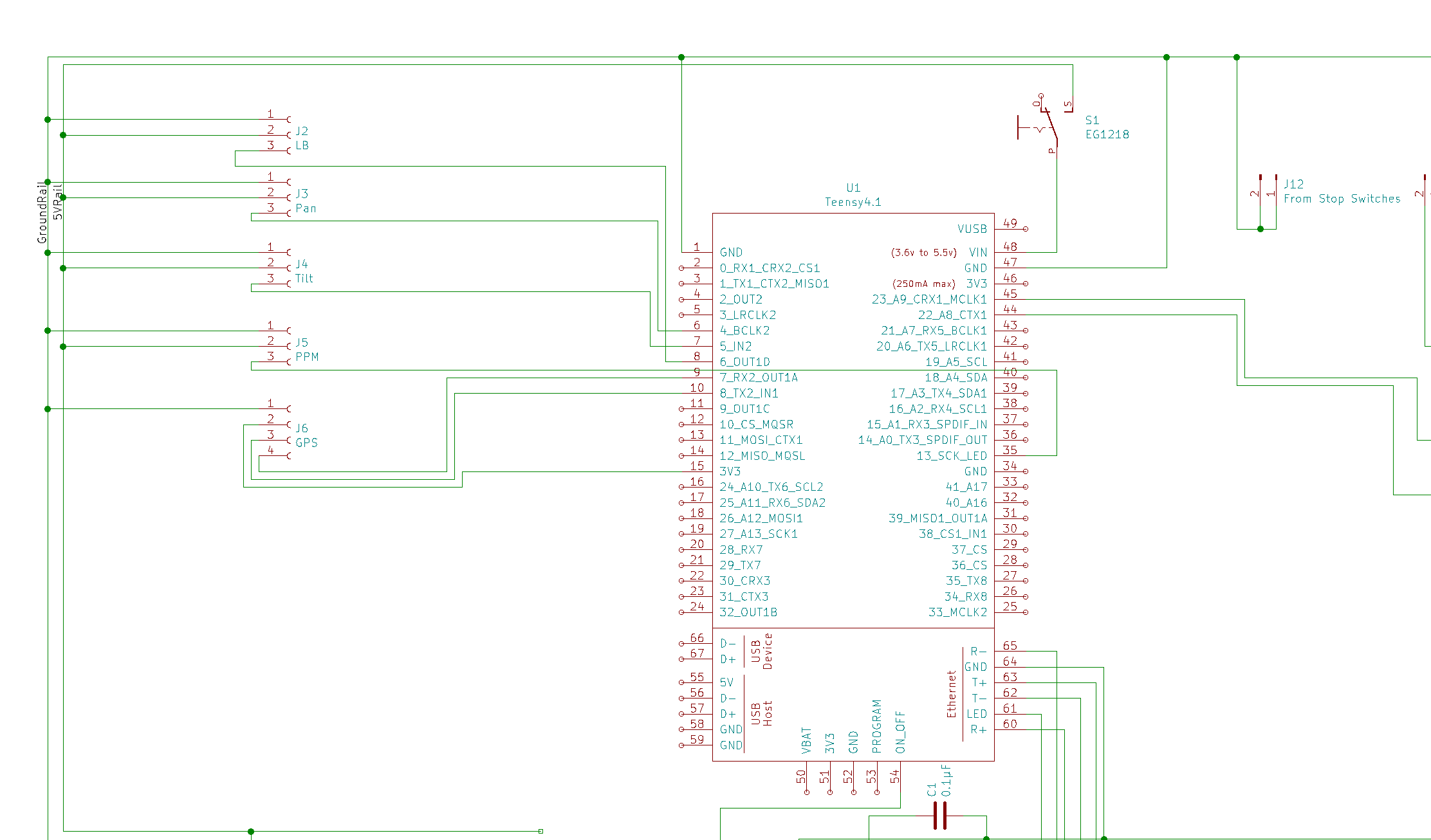

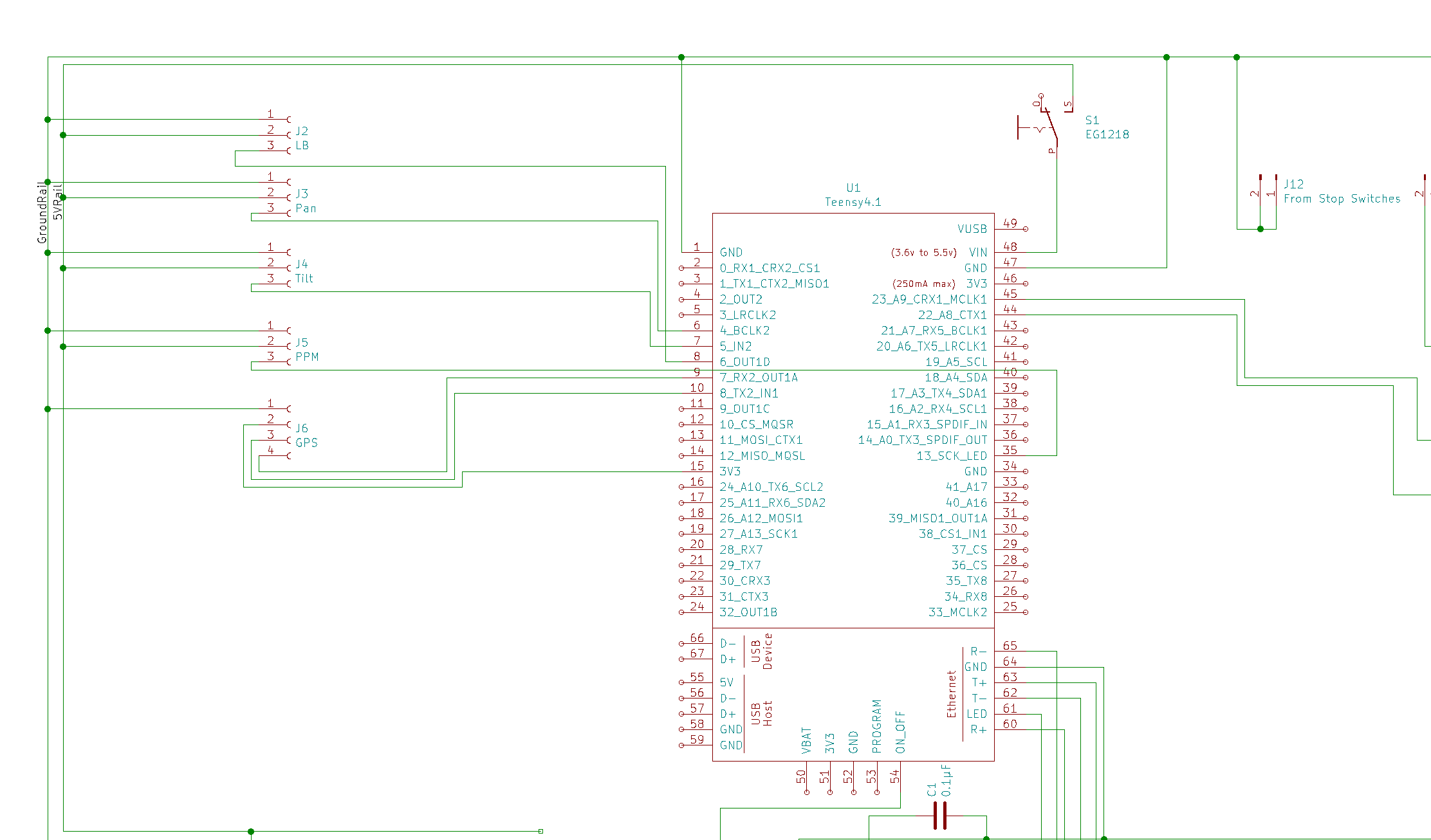

- Create circuit schematic (using KiCad)

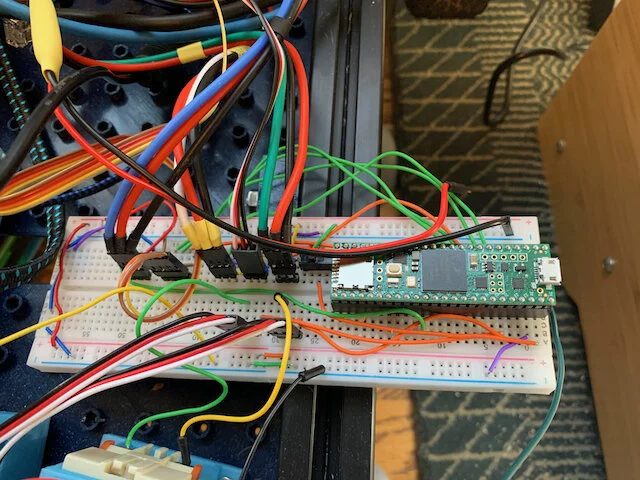

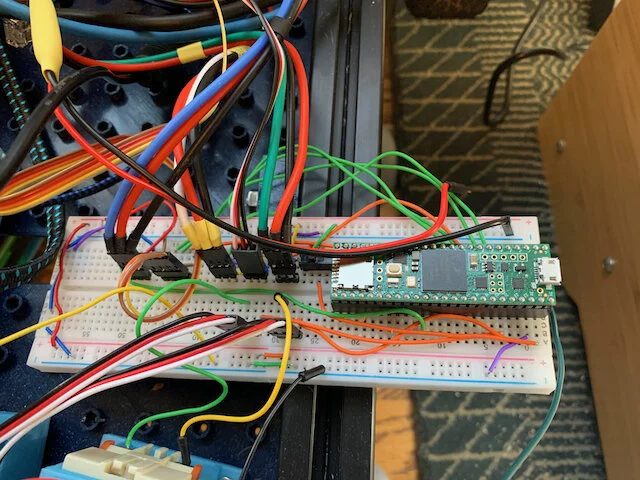

- Test design on breadboard

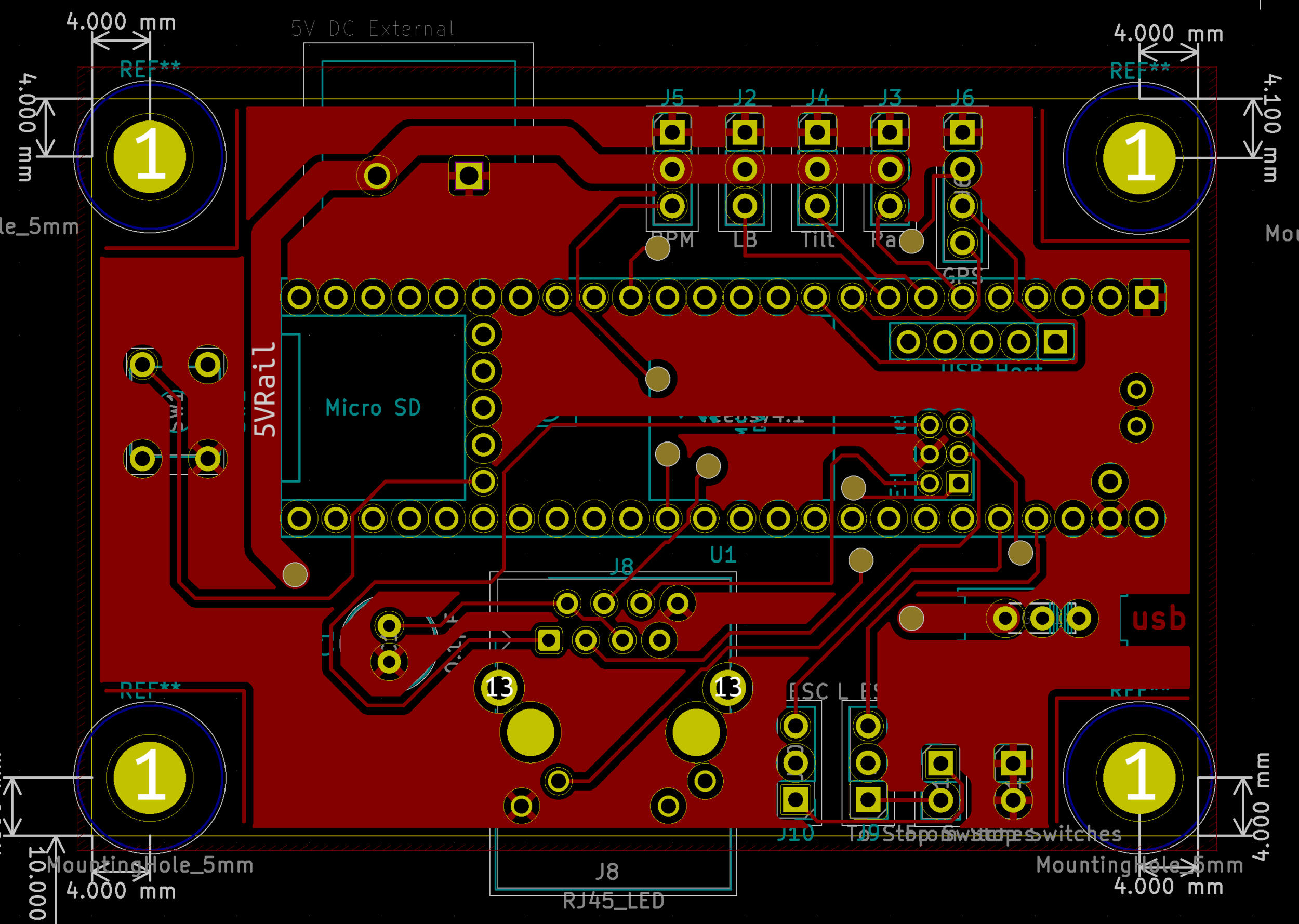

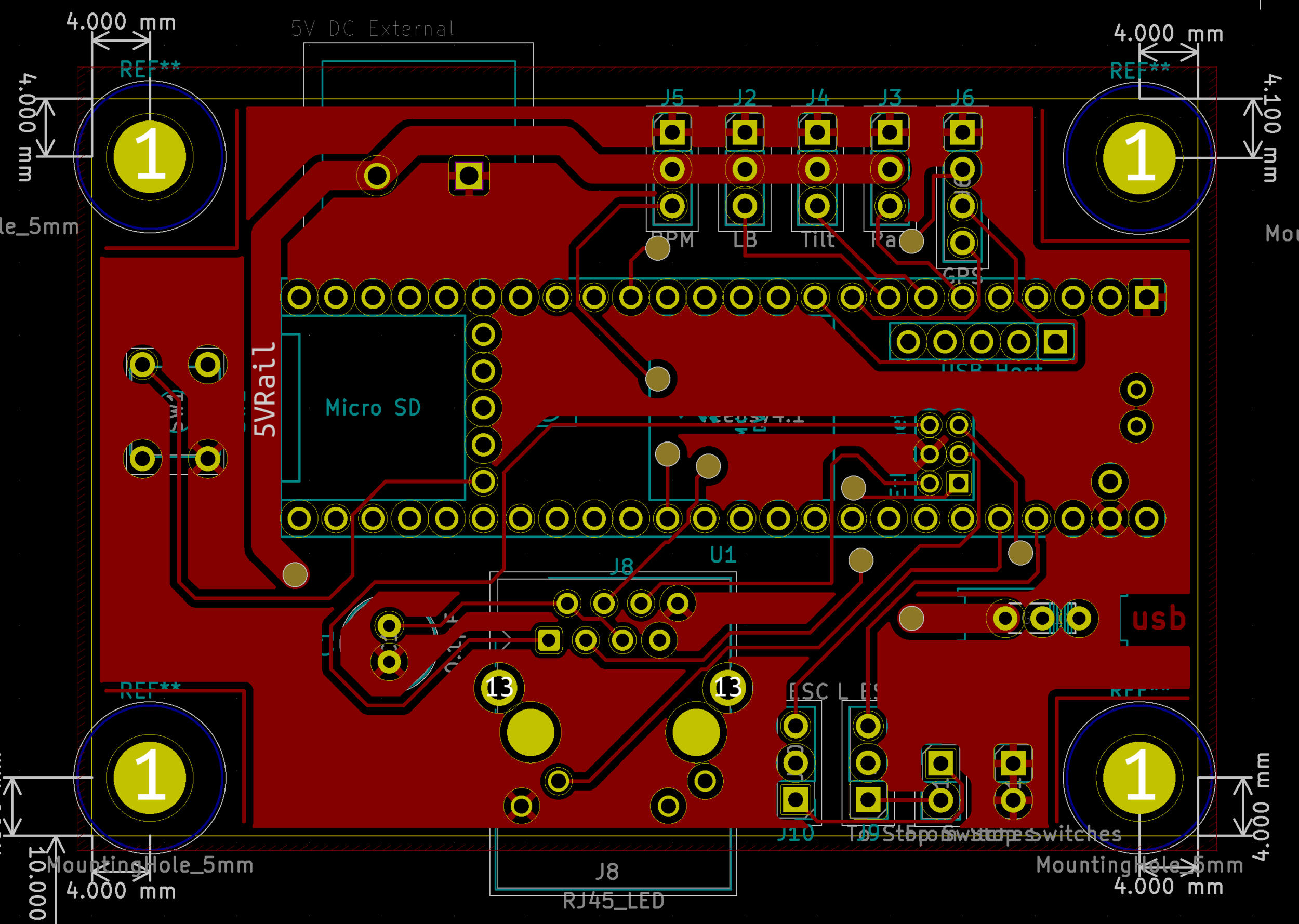

- Create board layout in KiCad

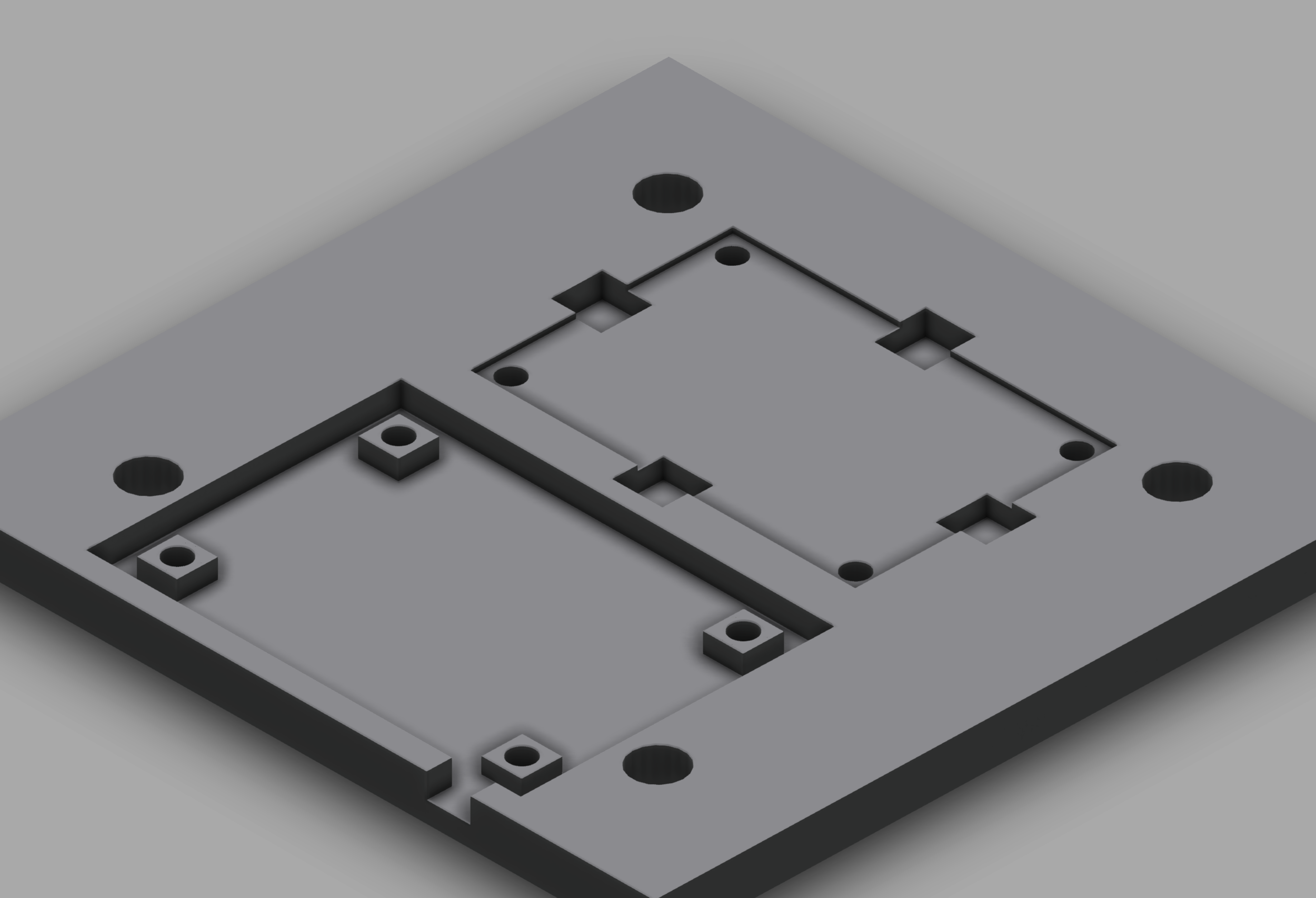

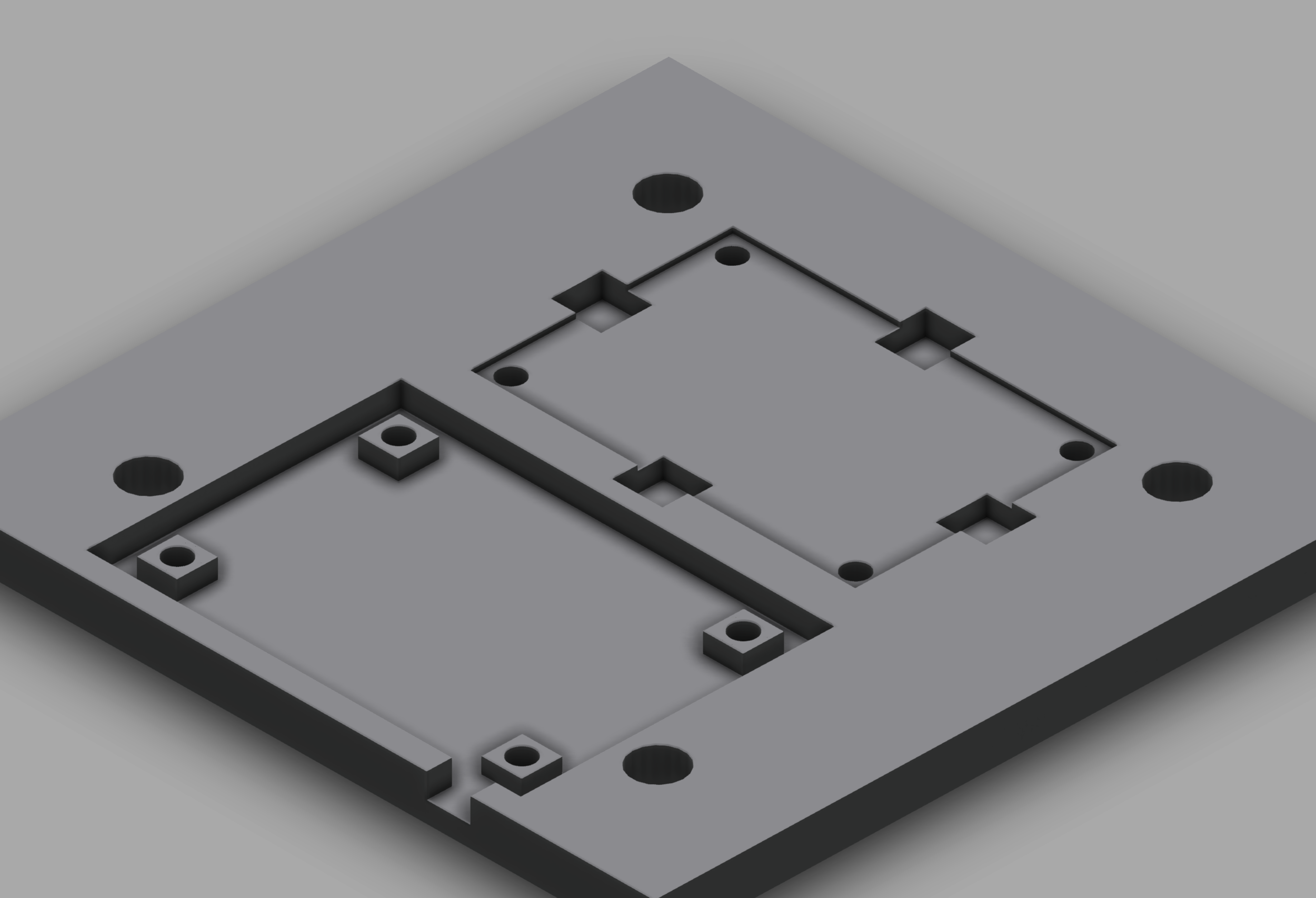

- Make a jig for double-sided milling

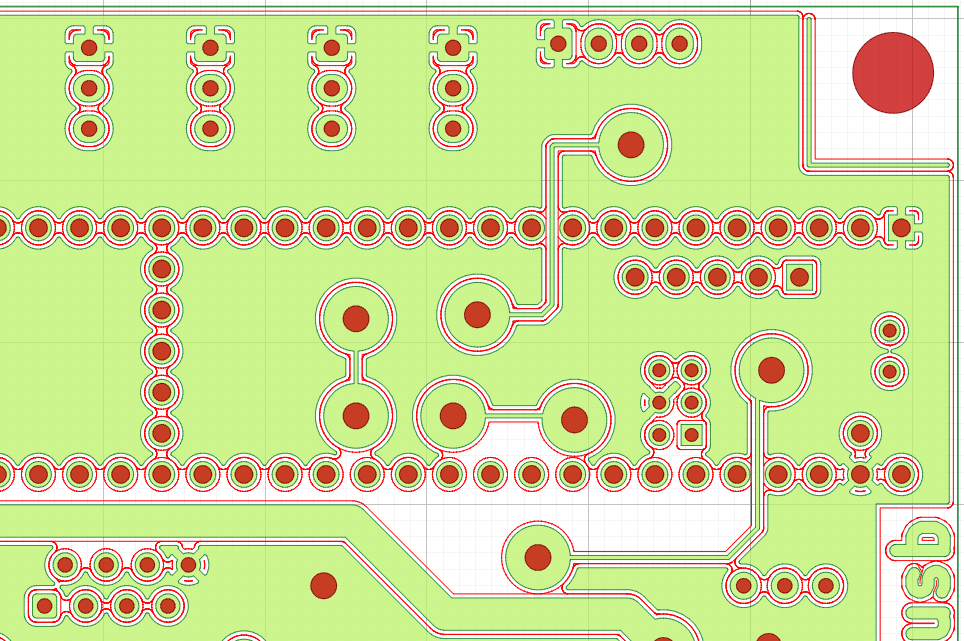

- Prepare G-code files

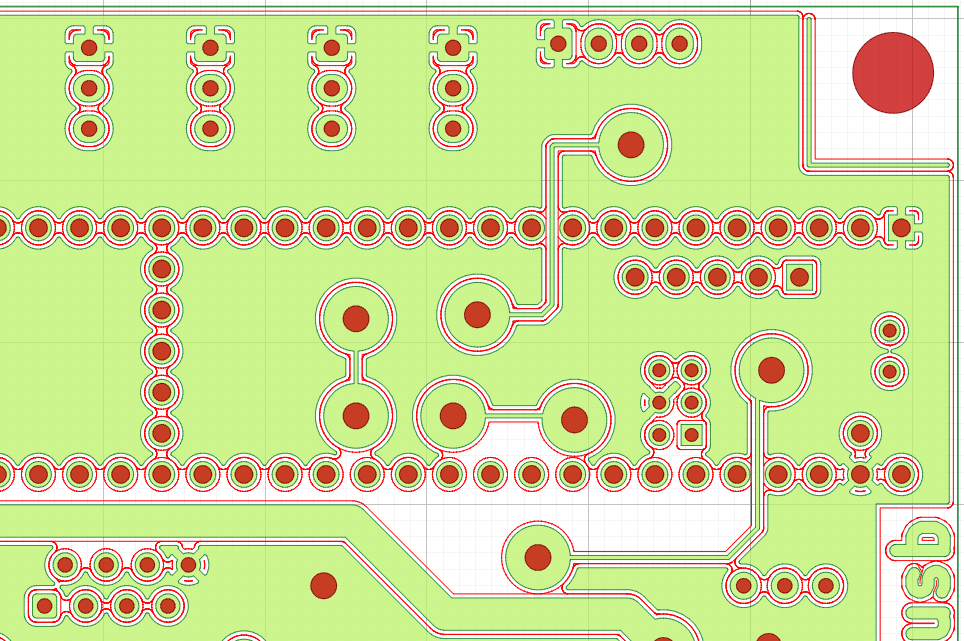

- Mill and drill the PCB

Hardware

- Carbide 3D Nomad 3 CNC machine

- 3/8" HDPE stock for jig material

- FR1 copper clad blanks (2"×3" double-sided)

- BitZero2 probe

- 1mm carbide drill bits

- Fine-tipped carbide scribe for scratch milling

- M3 rivet nuts for PCB mounting

Software Tools

KiCad

Open source PCB design software for creating schematics and board layouts.

FlatCam

Converts Gerber and Excellon files to G-code. Version 8.993 Beta recommended for usability. Windows installation most reliable.

bCNC

Alternative CNC controller with auto-leveling capabilities. Performs better on Windows/Linux than macOS. Steeper learning curve than Carbide Motion.

KiCad Board Layout Tips

- Set trace clearance to 0.34mm for tight routing

- Plan which side will be soldered (design accordingly)

- Use Edge.Cuts layer for PCB borders

- Trace power lines first, then signals, then ground fills

- Create fence traces around mounting holes to prevent bit collisions

- Use tiny M3 screws/nuts as vias (4mm via size, 1.6mm drill)

- Select breadboard-compatible components (2.54mm pitch)

FlatCam Parameters for Scratch Milling

- Tool diameter: 0.5mm

- Cut depth (Z): -0.35mm

- Travel height: 3mm

- Feed rate X-Y: 2500mm/min

- Spindle speed: 0 (passive scratch method)

Key Takeaways

- Home PCB milling is viable but requires mastery of multiple software tools

- Scratch milling (rather than full isolation routing) produces faster results

- Precise jig design is critical for double-sided alignment

- Auto-leveling compensates for uneven copper clad surfaces

- One-time projects may be better served by commercial PCB manufacturers

Resources